Intent tooling has the experience and capability to learn ,understand , adapt customer’s quality standards , manufacturing methods to achieve the best result effectively . The fully 3–D designs transition through seamlessly to the production floor. Intent also offers part design, as well as moldability analysis and revision to current customer parts, ensuring the highest quality tool. By using software tools that automate much of the design process Intent-tooling can produce injection molds in as little as four days. With our streamlined electrode design process intent has achieved delivered design in very short time.

Our highly skilled team of designers, engineers and technicians ensure that each mold is delivered in the shortest lead time possible, at competitive prices with the highest levels of accuracy and quality.

Our technicians use the latest machining techniques. Advanced 5 axis CNC machining, and programming capability results in improved accuracy and reduced lead times. EDM capabilities allow us to take advantage of unique tool designs as well as around the clock processing.

Final detailing, polishing, fitting and assembly are closely monitored by our team of experienced value stream managers. The performance of the mold is tested prior to delivery, ensuring each tool reflects the quality and reliability that customers have come to

- Rapid prototyping

- Soft tool prototyping

- Gauges

- Fixtures

- Program management

- Onsite support

- Production tooling

- Process review

Complex Molds

Intent Design designers have extensive experience with large complex molds. We excel at optimizing the design to make manufacturing fast and simple. We work towards paperless machining which is faster and efficient by completing the entire design in 3D.

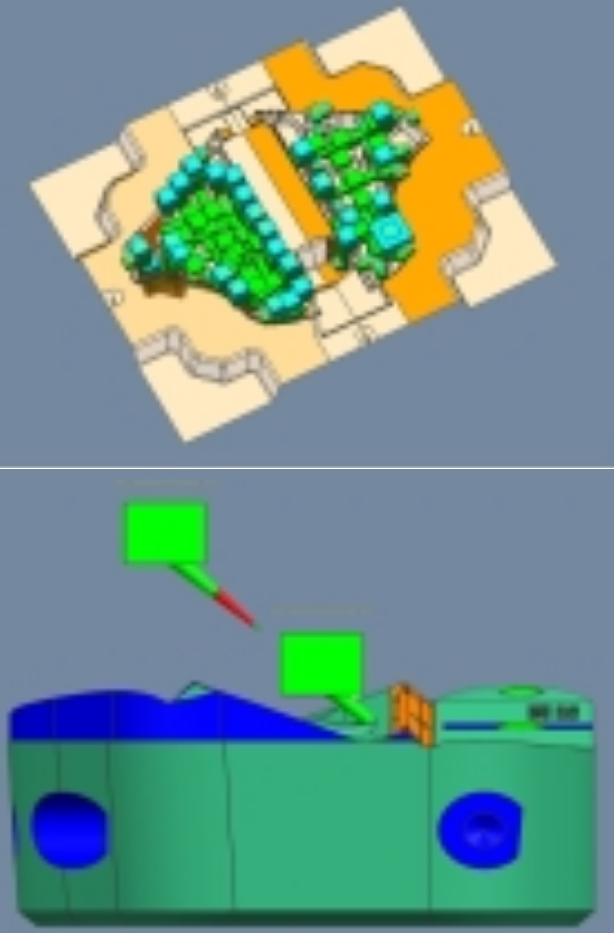

Parting lines

When building a parting line surface, Intent designers focus on creating simpler geometries such as planar or cylindrical surfaces which as easy to machine.

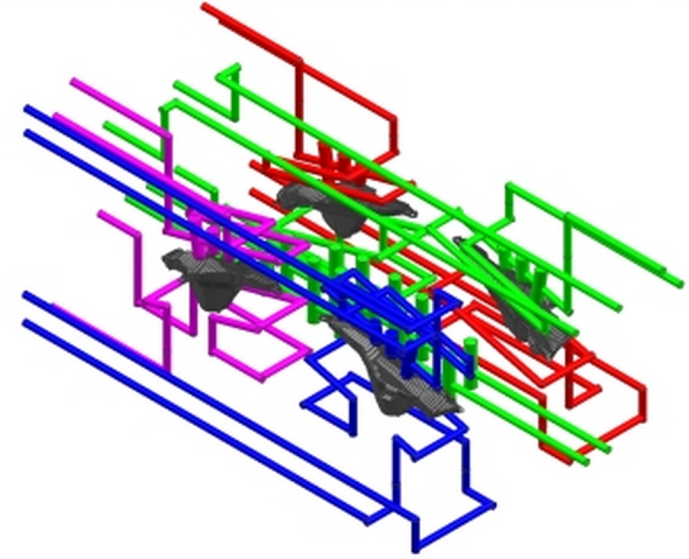

Cooling

Cooling is always a challenge when it comes to comples and large mold. Intent Design engineers have the knowledge and experience that they build in to the tools in order to allow efficient cooling, thereby improving the quality and reducing the cycle time.

EDM

Intent Design engineers creatively balance the three key parameters to deliver optimized EDM solutions.

1. Cost the RAW material for electrode 2. Machining time of electrode 3. Actual EDM machining time

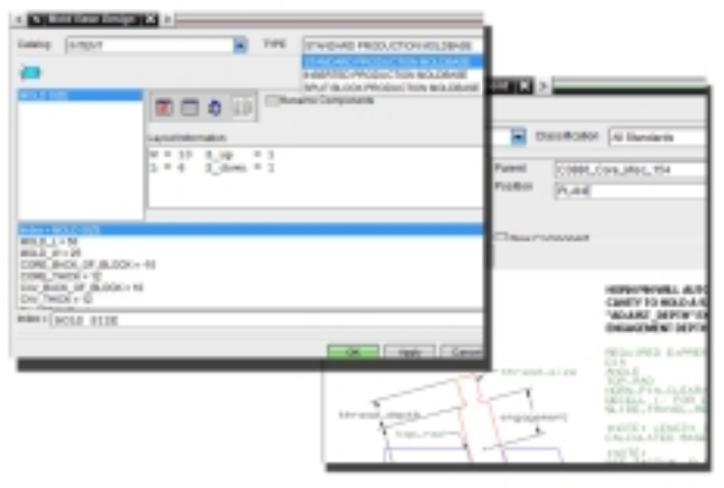

Standardization

We work with our customer’s shop to deliver standard library, customized mold bases, and customer documentation to generate the desired parts with a single mouse click.

We have over 10 years’ experience designing high quality plastic injection molds for small to large sized parts that are used in the automotive, medical, electrical, electronic, connector, consumer markets.

- Part feasibility studies

- Plastic part product design reviews for manufacturability

- Mold flow simulation analysis

- Complete design of precision plastic injection production molds

- Electrode extractions, design and planning

- Fully Parametric Custom mold base library builds for NX8.5 Moldwizard

- Customizing NX7.5 to improve the productivity

- Plastic part product design

Please give us a call at 248-381-5930 or email Info@Intent-Design.com to discuss your tooling needs.