Innovation and technology leader of advanced automotive components and systems.

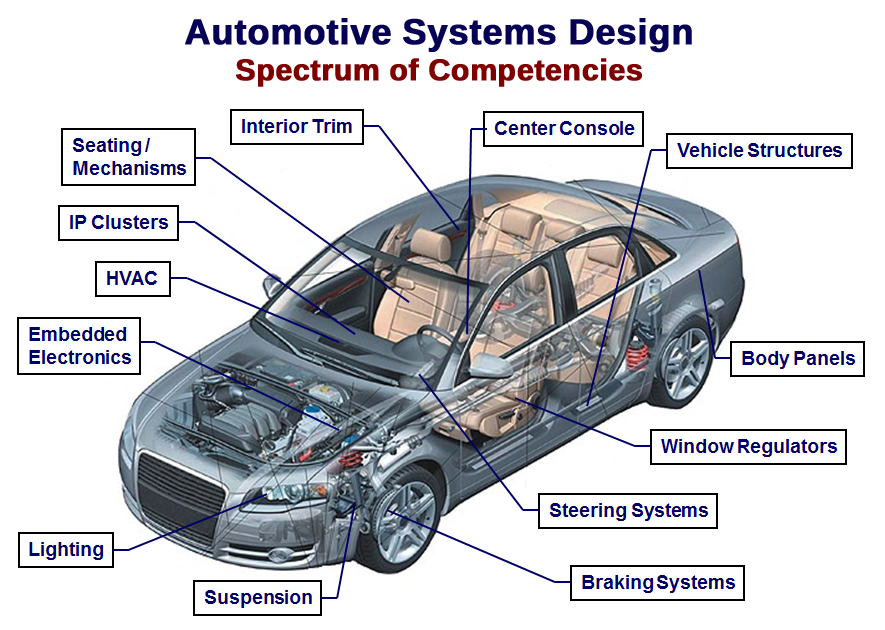

Our automotive product engineering design experience includes:

- Automotive Interiors and Exteriors

- Seating systems

- HVAC systems

- HVAC

- Transmission Systems

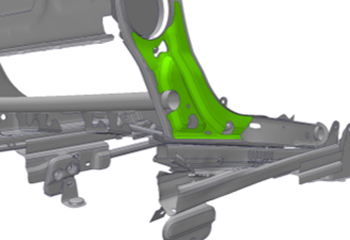

- BIW

We provide expertise in major design and engineering tools, including:

| CAD | AutoCAD, CATIA, IDEAS, Pro-E, Solid Edge, SolidWorks, Unigraphics |

|---|---|

| PLM | Team Center, VPM |

| CAE | Abaqus, ANSA, HyperWorks, LS Dyna, Madymo, Radioss, VCD/VCM, Moldflow |

We have applied our extensive capabilities to deliver complex technology-driven solutions in numerous worldwide automotive manufacturing systems applications. Our diverse cross functional team of Mechanical, Electrical, Plastics, Embedded Systems, Prototype and Manufacturing Engineers constantly push the limits of technology in product design and development, ensuring the success of each project.

We provide complete Automotive Seat System Engineering

Intent Design is a world-class provider of Engineering and Design solutions for seating mechanisms that are competitive in both mass and cost without affecting the performance and function.

Areas of Expertise

- Industrial Design

- Structures

- Mechanisms

- Foam Development

- Plastics

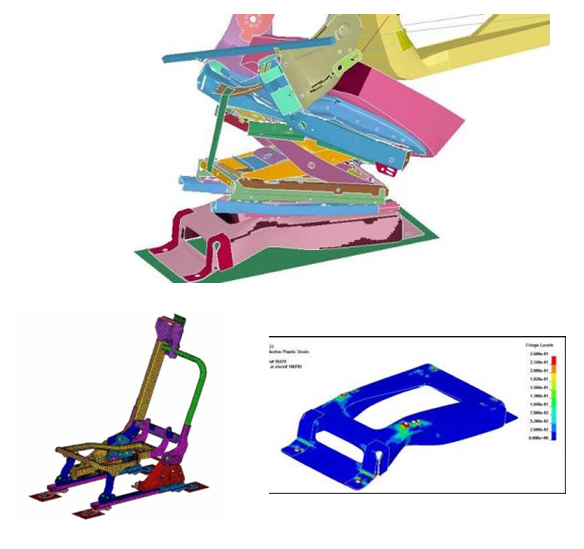

- Finite Element Analysis

- Prototype Development

- Testing and Validation Support

- Comfort Analysis

- Value Engineering

- DFSS

- Cost Analysis

- Thermal heating and cooling

- Electro-mechanical components

- Human Factors

- Structure

- Controls, wiring and motors

Case Study: Automotive Seat Design 1

Tasks we performed:

- Problem Analysis, Documentation

- Tolerance Stack Revision and new GD&T Scheme Development

- Multiple Two and Four Point Installation Jig Design Proposals

- Thirteen Improvement Suggestions

- Revised Construction and Assembly Methods

- Mechanical Design and Engineering of Affected Parts and Assemblies with FEA

- Finalized Jig Design and Engineering with Full 3D Solid Model Documentation and Fabrication Direction

- Senior Level Program Management and Customer Support

Our Results:

- Tolerance Stack and Part Quality Improvement Between 25.6% and 63.4%

- Labor Saving Average 43.5%

- Drastically Reduced Need for Multiple Post-Installation Adjustments in Factory

- Substantial Part Cost and Part Count Reduction

- Future Improvement Programs Identified

- Satisfied Customer

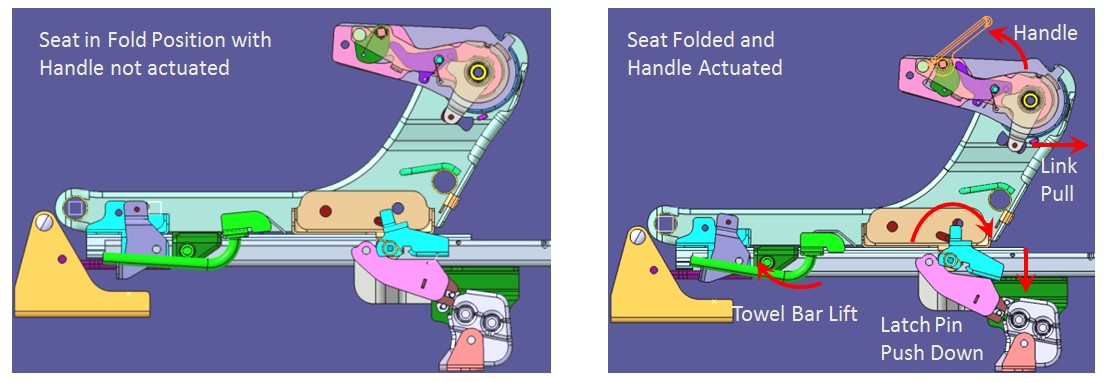

Case Study: Automotive Seat Design II

- Developed a creative interlock design solution for an Automotive Tier 1

- Reduced part count by 40% over the existing design.

- Reduced product cost for the Interlock by 30%.

- Interlock packaged without affecting Foam, Trim , Plastics and comfort

Case Study: Automotive Interior Design Engineering

- Reduced part count by 30% over the existing mechanism.

- Reduced product cost for the mechanism by ~40%.

- New mechanism packaged without impacting other components

Cost and Weight reduction on the existing Stow n’ Go mechanism - Contracted by Chrysler.

- Benchmarking and preparing feature matrix for comparison.

- Design & development of systems & components – Seats, Instrument panel, Console, Door trims, Roof trims & Parcel shelf, Sound proofing, Pillar trims & Boot trims.

- Feasibility study, layout creation & layout check for seat frame assembly & sub components.

- Kinematic model creation for clash interference checking and interface analysis.

- FEA validation for systems & subsystems, performance & compliance testing for no prototype approach.

- Virtual, Rapid & Physical prototyping.

We develop automotive world-class interior trim solutions with Class A surfaces that are aesthetically good and appealing. Our Services Include: